良工閥門套筒調節閥概述:

良工套筒調節(jie)(jie)閥(fa)(fa)由主閥(fa)(fa)、電(dian)(dian)磁先(xian)(xian)(xian)導(dao)(dao)(dao)閥(fa)(fa)、針閥(fa)(fa)、球閥(fa)(fa)、微過(guo)濾器、壓力表(biao)組成液(ye)控(kong)(kong)接(jie)管系(xi)(xi)統(tong)(tong)。電(dian)(dian)磁先(xian)(xian)(xian)導(dao)(dao)(dao)閥(fa)(fa)可遠(yuan)(yuan)程(cheng)控(kong)(kong)制閥(fa)(fa)門(men)的(de)開啟和(he)(he)關(guan)閉(bi)(bi)。通過(guo)增加額外的(de)設備,可以控(kong)(kong)制開關(guan)的(de)速度(du)。電(dian)(dian)液(ye)控(kong)(kong)制閥(fa)(fa)采用(yong)先(xian)(xian)(xian)導(dao)(dao)(dao)閥(fa)(fa)控(kong)(kong)制閥(fa)(fa)門(men)的(de)開啟和(he)(he)關(guan)閉(bi)(bi)。電(dian)(dian)液(ye)調節(jie)(jie)閥(fa)(fa)產(chan)品廣泛應用(yong)于(yu)(yu)城市(shi)供水管網系(xi)(xi)統(tong)(tong)和(he)(he)高層建筑及生活區等城市(shi)供水工程(cheng)中(zhong)。600X電(dian)(dian)動(dong)控(kong)(kong)制閥(fa)(fa)是(shi)一種(zhong)液(ye)壓操(cao)作閥(fa)(fa),以電(dian)(dian)磁閥(fa)(fa)作為(wei)先(xian)(xian)(xian)導(dao)(dao)(dao)閥(fa)(fa)。常(chang)用(yong)于(yu)(yu)給(gei)排水和(he)(he)工業系(xi)(xi)統(tong)(tong)的(de)自(zi)動(dong)控(kong)(kong)制。控(kong)(kong)制響應準確、快速。管道系(xi)(xi)統(tong)(tong)可根(gen)據電(dian)(dian)信號進(jin)行(xing)遠(yuan)(yuan)程(cheng)啟閉(bi)(bi),實現遠(yuan)(yuan)程(cheng)操(cao)作。600X電(dian)(dian)動(dong)調節(jie)(jie)閥(fa)(fa)可替代閘閥(fa)(fa)和(he)(he)蝶(die)閥(fa)(fa)用(yong)于(yu)(yu)大型電(dian)(dian)動(dong)操(cao)作系(xi)(xi)統(tong)(tong)。閥(fa)(fa)門(men)關(guan)閉(bi)(bi)速度(du)可調,關(guan)閉(bi)(bi)平穩,無壓力波動(dong)。電(dian)(dian)磁閥(fa)(fa)可采用(yong)交流220V或(huo)直(zhi)流24V供電(dian)(dian),并可根(gen)據各(ge)種(zhong)場合選擇(ze)常(chang)開或(huo)常(chang)閉(bi)(bi)。

當閥(fa)(fa)門(men)從(cong)進水(shui)端供水(shui)時,水(shui)通過針(zhen)閥(fa)(fa)流(liu)入主(zhu)閥(fa)(fa)控(kong)制(zhi)(zhi)(zhi)室(shi)。電(dian)磁先導(dao)閥(fa)(fa)打開時,控(kong)制(zhi)(zhi)(zhi)室(shi)內(nei)的(de)(de)水(shui)通過電(dian)磁先導(dao)閥(fa)(fa)和球(qiu)閥(fa)(fa)流(liu)出。球(qiu)閥(fa)(fa)開度大于針(zhen)閥(fa)(fa)開度時,主(zhu)閥(fa)(fa)控(kong)制(zhi)(zhi)(zhi)室(shi)內(nei)壓(ya)(ya)力很低,主(zhu)閥(fa)(fa)處(chu)于全開狀態。電(dian)磁先導(dao)閥(fa)(fa)關(guan)閉(bi)時,主(zhu)閥(fa)(fa)控(kong)制(zhi)(zhi)(zhi)室(shi)內(nei)的(de)(de)水(shui)不能流(liu)出,控(kong)制(zhi)(zhi)(zhi)室(shi)加壓(ya)(ya),推動(dong)膜(mo)片(pian)關(guan)閉(bi)主(zhu)閥(fa)(fa)。

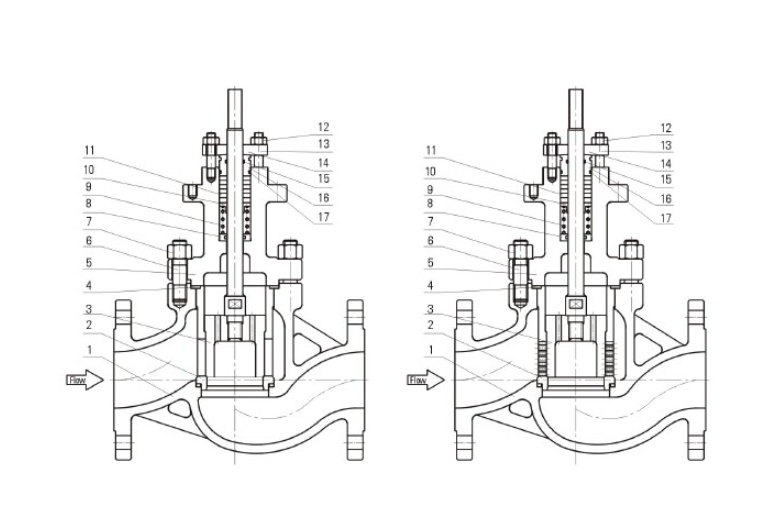

良工套筒調節閥ZDLM圖片結構圖:

良工閥(fa)門套筒調(diao)節閥(fa)技術(shu)參(can)數:

公稱通徑mm | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | ||

額定流量系數Kv | 2、3.2、 | 16 | 25 | 40 | 63 | 100 | 250 | 400 | 630 | 1000 | ||

公稱壓力MPa | 1.6 、 6.4 | |||||||||||

行 程mm | 16 | 25 | 40 | 60 | 100 | |||||||

流量特性 | 直線、等百分比 | |||||||||||

介質溫度oC | -20~200(常(chang)溫);-40~450(中溫);-250~-60(低溫) | |||||||||||

法蘭尺寸、型式 | PN16:按JB78-59光滑式 | |||||||||||

閥體 | 公稱壓力 MPa | 1.6 | 常溫: HT200ZG230-450ZG1Cr18Ni9Ti | |||||||||

6.4 | 常溫: ZG230-450ZG1Cr18Ni9Ti | |||||||||||

中溫: ZG230-450ZG1Cr18Ni9Ti | ||||||||||||

低溫: ZG1Cr18Ni9Ti | ||||||||||||

良(liang)工閥(fa)門(men)套筒調節(jie)閥(fa)性能參數:

公(gong)稱通徑(jing) mm | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | |

配電動 | ZDLM | 361LSA-20 | 361LSB-30 | 361LSB-50 | 361LSC-65 | 361LSC-99 | |||||

ZDLM2 | 361LSB-30 | 361LSB-50 | 361LSC-65 | 361LSC-99 | 361LSC-160 | ||||||

動作速度mm/s | ZDLM | 2.1 | 3.5 | 1.7 | 3.4 | 2.0 | |||||

ZDLM2 | 3.5 | 1.7 | 3.4 | 2.0 | 1.0 | ||||||